EnvironMolds Casting Resin

SP30001R

Applications

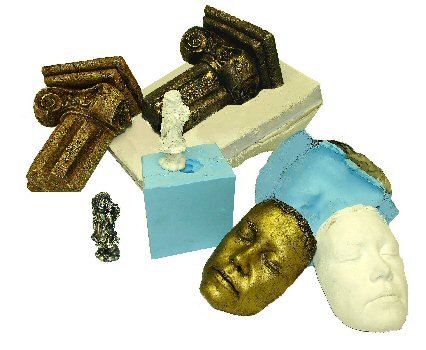

Environmolds' Poureable Casting Resin is used to make castings from rigid and flexible molds. Some of the most common uses of Mark 2 are point-of-purchase displays, rapid prototypes, special effects, and sculpture reproductions. However, it can be used for any application that requires a lightweight, hard plastic.

Characteristics

Environmolds' Pourable Casting Resin is a two-part polyurethane casting system. it is mixed one-to-one by volume and cures at room temperature. it produces a lower exothermic temperature than other, begins to gel in 1.5 minutes, and cures to a white color.

Instructions for Use Prepare Mold

Before you begin to cast a polyurethane mold, you must prepare the mold by applying the appropriate release agent (we recommend Artlube100). Apply the release agent sparingly, while coating all internal surfaces of the mold. Too much release agent may cover the details of the mold. You should allow the release agent to dry approximately 10 minutes before you pour the casting. Please note that silicone molds do not require a release agent. If you want to use an in-mold paint, like CilCoat, you should apply it after the release agent dries.

Measure Curative and Prepolymer

Using two clean, dry, plastic containers of equal size, measure equal amounts of the curative (part A) and the prepolymer (part B). If you want to use a filler or powder, use another clean, dry, plastic container to measure the filler or powder.

Do not measure more it than you can pour within its 2 minutes pot life. If you have a large mold that requires more it than you can pour in 1.5 minutes, you may use a rotational casting method or pour it more than once (if you pour Mark 4 more than once, you should do so immediately).

Mix Filler or Powder into Curative and Prepolymer

If you want to use a filler or powder, mix half of the filler or powder into the curative and the remaining half of the filler or powder into the prepolymer before you mix the curative and prepolymer together.

Mix Curative and Prepolymer

Note: Once you mix the curative and prepolymer, you have approximately 1.5 minutes to pour the casting.

After you prepare the mold, measure the curative and prepolymer, mix the filler or powder into the curative and prepolymer (optional), you are ready to pour the curative and prepolymer into another clean, dry, plastic container. Combine the two ingredients for approximately 30 seconds, being careful to prevent air bubbles from forming. Use a plastic or metal utensil to mix it.

Pour Casting

Although it gels quickly, you should take your time to carefully pour it into the mold. The best way to pour a casting with it is to tilt your mold slightly and pour into one spot of the mold. Pour slowly so that any air bubbles that may have formed during mixing can break over the lip of the container as it pours out.

Demold and Cure Casting

Once you have poured your casting, do not disturb the mold or demold the casting for 8?15 minutes. Although you may work with your cast in as little as 15 minutes after demolding, we recommend that you allow your cast to cure for 30 minutes for best results. You may post cure your cast for 6 hours at 160° F (72° C). After Mark 2 has cured, you may turn, drill, grind, sand, and paint it.

For more information on polyurethane resin please click here.